Every food has a unique, and invisible, chemical “fingerprint.” A researcher from Purdue University has discovered a quick and portable way to identify that fingerprint and sniff out food fraud on the go.

Let’s say there’s a food you suspect isn’t quite as advertised. Maybe that cheese that’s supposedly been aging for five years doesn’t have the right funk or the saffron you bought doesn’t seem the right shade of red. How would you go about testing it? What would that even look like?

Chemically, we have the ability to detect these differences in foods. If you send it off to an analytical chemist, they can pop the suspect food in their mass spectrometer—worth about half a million dollars and the size of a large closet—and let you know fairly precisely if there’s anything fishy with your fish.

That’s not so accessible for the average shopper. Bartek Rajwa, a professor of bioinformatics at Purdue University, kept this issue in mind when he started looking at ways to detect food fraud. Was there a system that was relatively affordable? Could he make it portable? Could he find a way to have more immediate results, instead of waiting for weeks in a traditional lab test?

In a word: yes.

But it took him more than a few tries. “Food is obviously a very complex matrix,” says Rajwa. “If we could reproducibly register some kind of a unique pattern associated with the specific product, then, in theory, that might help [identify fraud].” Rajwa began looking for the food’s “fingerprint,” as he called it; the unique atomic makeup that would tell him definitively which slice of ham came from pork that had been cured for years in a Portuguese cave and which slice of ham was just painted to look that way.

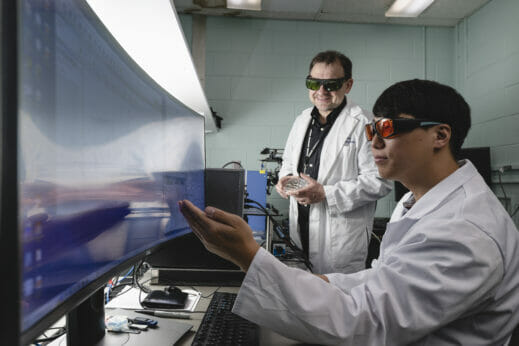

Purdue researcher Bartek Rajwa and Purdue postdoctoral fellow Sungho Shin use LIBS spectroscopy to collect data from the surface of an orange. Photography courtesy of Purdue University.

A laser focus

The traditional method of this kind of testing is time consuming. You take a swab of a sample food, let bacteria grow on a sterile plate, then test the bacterial colonies that grow and discover the particular ingredients in the sample. But if there are 500 different bacteria colonies that pop up on your sample, that’s going to take a while.

After playing around with ways of identifying the chemical components of bacteria from various sample foods, Rajwa hit upon repurposing a technology that was already in use to test metal alloys.

Say you have a scrap yard, with heaps of metals from various vehicles, appliances and other machinery. “You have to find out what type of alloy you have before it goes to recycling,” explains Rajwa. That system exists, called a laser induced breakdown spectroscopy (LIBS). “It’s a fascinating tool. It basically hits an object with a laser and it creates a very very tiny plasma plume…There’s a formation of light when the plasma cools. You have a tiny explosion of fireworks, but they are microscopic.” It’s in this miniature fireworks explosion that elemental peaks form. When using these lasers on a metal alloy, it’s easy to see different peaks for iron, aluminum, nickel or whatever you might be working with.

Rajwa decided to try and modify the LIBS testing equipment to see if it could be used on other compositions; namely, food.

He tried the sample with Gruyere cheeses, made from dairy farms in different regions of Switzerland. The cheeses themselves were nearly identical, but, in theory, there should be differences in the chemical makeup based on what the cows were fed and where they were raised.

It worked; Rajwa was able to differentiate between cheese produced 50 miles apart. “From that point on, we thought this was so cool. Let’s try it with coffee. Let’s try it with spices,” he says. Some foods are easier to trace than others. In the original cheese example, there’s a roughly 85-percent success rate. For something much more cut and dry, such as synthetic vanilla versus true vanilla extract, the success rate shoots up to nearly 100 percent. And most food frauds aren’t that sophisticated, Rajwa says, making them easier to detect. “If we’re talking about cheeses, it’s not generally two different containers of Gruyere. [It’s usually] parmesan and aged cheddar with cellulose. I guarantee you that telling the difference between parmesan and aged cheddar with cellulose, it’s not even a challenge.”

Purdue researcher Bartek Rajwa and Purdue postdoctoral fellow Sungho Shin use LIBS spectroscopy to collect data from the surface of an orange.

A fingerprint database

Of course, Rajwa needs to know how to interpret the results that he gets from the LIBS testing. The “fingerprint” of a food, or the atomic spectra that is seen in that mini fireworks blast, will be unique to each food. But how does he know if the fingerprint he’s seeing is the true fingerprint of that food? To do that, Rajwa and his team began creating a database of fingerprints that they can reference and are continuing to add to it with each further test. As their reference dataset grows, they further automate that system with machine learning to become even faster at detecting frauds.

Even the whirlwind supply chain on which many foods travel don’t have a meaningful impact on the individual fingerprints. If a food is processed into something else—that cheese being shredded onto a pizza, say—there would be different fingerprints associated with the constituent parts. But packaging, shipping and point of sale don’t change the chemical fingerprint of a food.

But this approach isn’t just about detecting a source of explicit fraud. Rajwa thinks it can be used to detect more insidious forms of fraud, too. “Nobody is going to necessarily put on the label that a certain cheese came from this or that valley. However, if this valley is associated with different farming practices, like organic, how do we know if it’s really from there? If there is a fingerprint associated with it, it’s very easy to verify.”

The best part about the testing equipment is that it’s already fairly plentiful and accessible. Rajwa repurposed the metal-testing device, similar in size and shape to a drill or a hairdryer, and gave it new software. Now, it’s not a metal scanner but a food fraud detector.

That’s not to say that Rajwa anticipates everyone will walk around with a portable laser scanner just to go to the supermarket. But with a wider distribution in the food industry, food processors, vendors, inspectors, even people doing spot checks at those very same supermarkets could use these scanners as a type of pre-screening. They could do an initial test on the spot, and the results would come back immediately. If the test indicates there’s an issue, then the inspector or food vendor could send a larger sample off to a lab for a confirmation and further testing.

Purdue researcher Bartek Rajwa uses a portable LIBS spectroscopy instrument to collect data from the surface of an orange.

A matter of trust

Beyond just detecting causes of fraud, Rajwa hopes the technology can be used to improve overall food safety. Generally, food inspectors take samples of food, send them off to a lab and results might come back weeks later. “We see this so many times, when you get a printed receipt from the grocery store. At the bottom it says, ‘If you bought peaches two weeks ago, they are recalled because of salmonella.’ Two weeks ago? Those peaches are gone! They’re eaten,” says Rajwa. But if vendors had access to portable, fast analysis, we might not find ourselves in the situations where safety issues worsen because of delays in the system.

However, the LIBS testing platform has its limitations. For more complex foods, such as cheese or cured meats, Rajwa is working on a second testing method using Raman spectroscopy. This uses light to measure energy levels, and it can detect specific organic molecules such as antibiotics or pesticides in food. Rajwa anticipates using the two tests together for a more complete look at the sample food.

Rajwa plans to continue testing his technology and expanding his research. But he hopes that the LIBS devices can make it out into the wider market; he sees them popping up at border patrol sites or traveling with restaurant inspectors as they make their rounds. First, though, there would need to be a large and comprehensive dataset of food fingerprints to reference.

Further testing is needed to see how easy it is for others to reformat the LIBS testers already on the market. It’s unlikely we’ll see anything available to the wider population anytime soon, but this kind of technology, when available on a larger scale, could increase trust and safety for consumers everywhere.

This story is part of ‘Phonies, Fakes and Food Fraud’, a special Modern Farmer series. See the full series here.

Thank you for the information! It’s fascinating and I’m excited it’s coming along, I hope it advances quickly. It is needed.

100% identical is very improbable but the most common type of fingerprint sensor on our phones only take a small portion of it and similarities at that scale became more plausible.